WhatsApp)

WhatsApp)

Browse the latest articles, photo galleries and videos relating to island . Cement Australia Bulwer Island Ball Mill email id list of cemant mill . Main Parts Of Ball Mills - Crusher USA 2014429-About main parts of ball mills-related information:ball end mill gashing based on a cam system the open mechanical engineering journal, 2012.

ball mill "aluminium powder" small scale – Gold Ore Crusher. small scale mining ball mill,plant india machine Equipment china for . This is a ball mill used for refining . Posts Related to ball mill "aluminium powder .

Like all ball mills, the speed and ball size have an effect on how the vertical ball mill works. Vertical ball mills often come with a variety of ball sizes (and have variable speed settings) for more efficient processing. Industrial Ball Mills. Industrial ball mills are much larger than the other types of ball mills.

nickel ore ball mill sizes dimensionsnickel mining crusher . nickel ore ball mill - lenins nickel ore ball mill sizes dimensions Rock Crusher Mill nickel ore ball mill sizes dimensions XSM is a leading global manufacturer of crushing and milling equipment (nickel ore ball mill sizes dimensions),XSM also supply. typical nickel plant process

Ball Mill In Alumina Refinary - galaxynorthavenue. ball mill in grinding procees of alumina refinary - YouTube. . Common grinding methods include continuous ball milling and air-jet milling. ball mill . ball mill alumina refinery - iwspl. ball mill alumina refinery - smartcme. Get help online

Our company is a heavy industry enterprise committed . Mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plant.Ball Mill Refinery .

The ball mill system consists of one turn disc (turn table) and two or four bowls. Usable Values of Nickel Ore and Nickel Concentrate Certified . Oct 23, 2014 . Usable Values of Nickel Ore and Nickel Concentrate Certified Reference . for 48 hr in a high-alumina ball mill to a final size of < 0.074 mm.

The rod mill was commissioned in 1966 and the refinery in 1993 (the refinery was permanently closed in 2005). SDL – INDUSTRIAL – Steel Drafting Ltd marsden point refinery upgrades. harvey farms grain storage feed. rod mill, australia << back .

Norilsk Nickel, nickel refining plant, Finland ... Manchester, refines it into alumina at a refinery... rod or ball mills and processed into a red slurry. LEGO ball mill - Hackaday 2 Nov 2010 ... This is a ball mill used for refining materials into a fine powder. [Jpoopdog] built it .

Attrition mill is a type of grinding mill by kinds of media to crush lump to powder-like substances. The impact can be rock on rock such as in an Autogenous Grinding (AG) mill, rock and a small ball charge (~10%), used in Semi Autogenous Grinding (SAG) mills, balls of various sizes in Ball Mills and less commonly these days, steel rods in Rod Mills.

Ball Mills, cement mill, slag mill, tube mill. Dry ball mills are effective grinding systems in the general range of 500 microns down to 5 microns. . blast furnace slag, calcined alumina, calcium carbonate.

Ball mill. A typical type of fine grinder is the ball mill.A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

Perry Videx offers used and refurbished vibrating ball mills and vibrating grinding mills. ... Plant - Petrochemical, Refinery & Asphalt (6) Plant - Pharmaceutical (4) ... Used Sweco model M18L urethane lined vibrating ball mill. 1/4 HP motor and cover. 3 phase, 60 cycle, 220 volt. Location: On Site at Perry (Hainesport, NJ ...

Alumina refining | alteo-alumina- ball mill alumina refinery, The Bayer process is the industrial route to produce alumina, named after its creator Karl Josef, Common grinding methods include continuous ball milling and air,Cylindrical Alumina Grinding Media Cylindrical Alumina Grinding Media High-density, ultra-high fired Burundum is the ideal medium for wet or dry milling High specific ...

Alibaba offers 1,257 rubber refining mill products. About 1% of these are mine mill. A wide variety of rubber refining mill options are available to you, such as ball mill, raymond mill. You can also choose from free samples. There are 1,248 rubber refining mill suppliers, mainly located in Asia.

Laboratory Ball Mill Machine, Price, Suppliers,Manufacturers . Berto Ball Mill (Chocolate Refining Machine) Chocolate refining process to produce cream for application for filling or coating with grinding method using steel ball.

Alumina ball for all sorts of ball mills, pearl mills, sand mills for the superfine grindings and dispersions of products with special quality requirements,such as: Zircon sand, Silicon dioxide, Calcite(GCC),Magnetic bands coatings for audio and video tapes, paint, pigment,coatings,Ceramic glaze, Titanium dioxide and so on.

Dec 21, 2016· 2 parallel SAG Mills each feeding 2 parallel Ball Mills (4 total). ... 3D Animation Demo & working site of Ball Mill - Duration: ... Animation of 2015 Explosion at ExxonMobil Refinery in Torrance ...

Nov 21, 2019· CONTACT US BE OWN REFINERY! info@proses-makina

May 09, 2018· Here's one to add to the "d mechanosynthesis" pile. According to this paper, you can do hydrogenation reactions in a stainless-steel ball mill, without any sort of noble-metal catalyst. The hydrogen is produced when you add some n-alkane or diethyl .

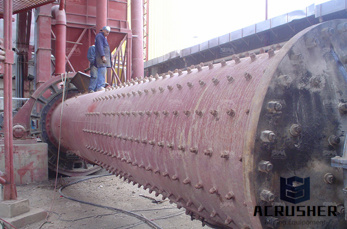

Nickel Refinery Ball Mill Metalock of Australia P/L completes Nickel Refinery Ball Mill Trunnion repair. Internal wear of Trunnion brought production to a grinding halt. 4 areas were badly worn with one section having gone completely through to the bearing journal.

Jun 11, 2019· Grinding in a ball mill is not the results of the ball media striking the wall of the mill with a particle in between. A properly run ball mill grinds the particles between the ball media. It must be run at sub critical speeds for this milling action to occur. Excess noise is usually the fault of running the mill at super critical speeds.

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semi-autogenous mills having between 100 and 1,000 ...

Ball mills for super-fine calcium carbonate. Ball mill classifier systems have been improved over time and are now capable of achieving much finer products. In the past, a particle size with a D97 of 10 microns was only possible. Now particle sizes down to a D97 of less than 3.5 microns can be achieved, with a D50 in the range of 1.5 microns.

WhatsApp)

WhatsApp)