WhatsApp)

WhatsApp)

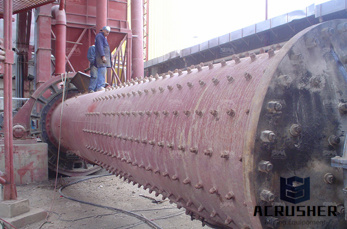

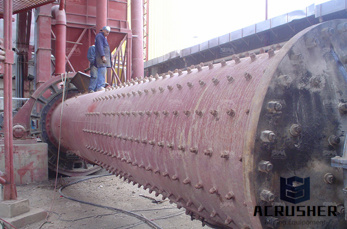

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 -50% of the mill volume and its size depends on the feed and mill size.

ball mill working and construction project. Construction And Working Of Ball Mill. ball mill working and construction project Ball Mill by Saraswathi.BPharmainfo. A ball mill is a type of grinder or mill used to mill the materials into fineParts,Construction, Ball Mill Working .

Construction Working Ball Mill Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users.

Project; About; Contact; ... construction and working of ball mill. Cement Ball Mill for Construction Manufacturer from Rajkot. We are one of the prominent manufacturers and suppliers of Cement Ball Mill for Construction. ... What is the working principle of ... Ball Mill Working principle: When the ball mill works, motor and speed reducer ...

Apr 24, 2015· Ball mill consist of a hollow cylindrical shell rotating about its axis. Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is ...

Jun 20, 2015· The effect of Ball Mill RPM speed going from sub-critical to super-critical helps understand the Ball Mill Working Principles of ball-on-ball VS ball-on-shell grinding. The Motion of the Ball Charge

Construction. A ball mill consists of a horizontally rotating hollow cylindrical vessel or shell with the ... Working principle of ball mill. Get Price. Karara Contracts Update - Gindalbie Metals Ltd. Jun 8, 2010 ... project construction and working capital, both of which are subject to ... ball mills have either been completed or are ...

Comments of Ball Mill Working And Construction Project; Ball mill - Wikipedia. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ...

working and construction of ball mill - raftingandcamping . ball mill types construction working advantage and, Ball Mill by SaraswathiB - Pharmainfo A ball mill is a type of grinder or mill used to mill the materials into fine powder in pharmaceutical industry.

Work included the installation of a variety of different components including a rod mill, ball mill, regrind moil, agglomerator, filter presses, conveyors, associated equipment, tanks and over 1800 spools of large bore piping. The project was valued at 22 million dollars and was completed over a 14-month time period, using 300,000 man hours.

To Study The Construction And Working Of Ball Mill. Construction and working of ball mill mirestcz ball mill principle construction working and use of oct 02 2018 hello friend im chadra prakash pathak from lucknow this video is make on the topic of ball mill from pharmaceutics1 watching this video and gain. Chat Online

ball mill principle construction working pdf ball mill-principle gujaratgenomics ball mill principle construction working pdf A ball mill is a type of grinder or mill used to mill the materials into fine powder in pharmaceutical industry working principle mode construction performance of ball mill.

ball mill construction and working - postcatcherin Know More. Ball Mill,, Principle construction Working and use 02/10/2018 Hello friend I'm chadra Prakash Pathak from Lucknow This video is make on the topic of Ball Mill from pharmaceutics-1,...

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nano-powder. The cylindrical jar is used as a mill that would rotate the ...

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

construction and working of ball mill_Ball Mill by Saraswathi.B - Pharmainfo Construction. A ball mill consists of a horizontally rotating hollow cylindrical vessel or shell with the length . Working principle of ball mill.

Hummingbird making short work of second ball mill project at Yanfolila gold mine Posted by Daniel Gleeson on 17th June 2019 Hummingbird Resources' plan to install a second ball mill and increase production capacity at its Yanfolila gold mine, in Mali, is tracking ahead .

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Scope of Work: Construction and installation of feed bin/ball mill feed conveyor, and main frame and ball mill; Installation of all pumps and pump hoppers; Fabrication and installation of all LP/ HP instrument air lines and piping brackets; All site fabrication and tie into main plant for supplementary feed ball mill

Mon Ball Mill Working And Construction Project . Mon Ball Mill Working And Construction Project 3. After turning on the ball mill, it must first be tested on the empty box. After ensuring that the contact surface between the box and the mechanical parts is sealed and well lubricated, the operation begins.

Working Principle & Operation. The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the ...

working and construction of ball mill Ball mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and .

The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill. These mills may be divided into three types ROD MILLS, BALL MILLS and AUTOGENOUS MILLS. In the first type, the ROD MILL, the ore is introduced into the mill.

ball mill principle construction working pdf. Working Principle Construction Performance Of Ball Mill. Working Principle Of Ball Mill Pdf, jspfoundationorg construction working pdf ball mill principle for bauxite crushing pdf, Ball mill is a horizontal cylinder, Chat With Sal working principal of .

WhatsApp)

WhatsApp)