WhatsApp)

WhatsApp)

Oct 16, 2019· Method of balls rolling on ball- rolling mills is one of the most modern production methods. Transversal rolling of balls from the round billet is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 10-15% to ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Find great deals on eBay for steel mill balls. Shop with confidence. Skip to main content. eBay Logo: ... Buy It Now +$7.50 shipping. 490 Sold 490 Sold. Watch ... 400 Series Stainless Steel Grinding Ball Mill Media Mixed 3/4"-2" Dia. Pre-Owned. $20.00. Buy It Now +$43.81 shipping. Watch.

When we buy a ball mill, the manufacturer's instructions will have detailed technical parameters, and generally give a range of production values.Usually, the output will remain normal when the ball mill is just put into production, but after a period of operation, there may be .

Aug 13, 2015· Vertical Mills. A significant portion of the cost to produce a ton of cement resides in the grinding costs. The industry standard for decades has been horizontal ball mills which rely upon heavy balls cascading inside a fast turning mill to crush the clinker into the fine cement powder.

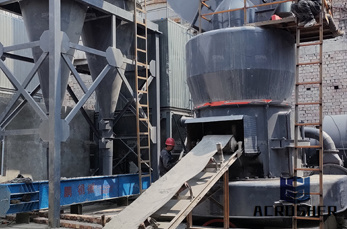

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Cement Ball Mill /cement Minn Grinding Balls /cement Mill Separator, Find Complete Details about Cement Ball Mill /cement Minn Grinding Balls /cement Mill Separator,Cement Ball Mill,Cement Minn Grinding Balls,Cement Mill Separator from Mine Mill Supplier or Manufacturer-Luoyang Zhongde Heavy Industries Co., Ltd.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill & ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

SILICON CARBIDE BALLS Silicon Carbide Balls are very high-cost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item.

Oct 12, 2017· Ball mill is a fine grinder. A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel. The ball charge of a SAG mill is about 29% to 30%. By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness.

Product Application. Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Aug 04, 2019· In China, for 5000t/d cement production line using a ball mill with closed...Cement Clinker Grinding Plant - Alibaba6441 Results ... Capacity 100-3000 TPD Cement Clinker Grind / Cement .

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case".

Gold Copper Ceramic Cement And Iron Ore Grinding Ball Mill, Find Complete Details about Gold Copper Ceramic Cement And Iron Ore Grinding Ball Mill,Cement Ball Mill,Ball Mill,Grinding Ball Mill from Mine Mill Supplier or Manufacturer-Luoyang Zhongde Heavy Industries Co., Ltd.

Ball Mill Balls, You can Buy good quality Ball Mill Balls, we are Ball Mill Balls distributor & Ball Mill Balls manufacturer from China market. English English French ... Mining and Cement use ball mill balls forged ball and cast ball grinding media balls As a leading global manufacturer of grinding media, we offer advanced, reasonable ...

Mar 03, 2015· Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier worldwide.A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Wind Swept Coal Stone Planetary Ball Spare Part Advantage And Disadvantage Cement Mill, Find Complete Details about Wind Swept Coal Stone Planetary Ball Spare Part Advantage And Disadvantage Cement Mill,Cement Mil,Ball Mill,Cement Ball Mill from Mine Mill Supplier or Manufacturer-Henan Hongji Mine Machinery Co., Ltd.

Cr:16 casting steel grinding balls for ball mill and cement plant . Process features of cast iron balls: Moulding process---pouing when the molten iron temoerature reaches 1500 C,using the teoperature difference between moletn iron and the molds this way,the ball can achieve internal organization of grain refinement and be moredense.menanwhile,the carvide is radially arranged .and such ...

Yantra Laboratory Ball Mill 2 kg Motor Driven Heavy Duty with 10 Big Stainless Steel Balls (15 mm) and 35 Small Stainless Steel Balls (8 mm) $385.00 $ 385. 00. FREE Shipping. Only 7 left in stock - order soon. Chicago Electric Power Tools 67631 Rotary Rock Tumbler, 3 lb. 3.8 out of 5 stars 192.

We can also buy surplus ball mills or sell on a consignment basis. From small Lab and Pilot Batch Mills to large Ball Mills, we source mills to suit your needs manufactured by Denver, , Allis Chalmers, Polysius, FL, Dominion, Hardinge, , and more. A ball mill is a cylindrical device used in grinding (or mixing) materials like ...

Ball Mill Liner / Cement Ball Mill / Ball Mill Machinery, Find Complete Details about Ball Mill Liner / Cement Ball Mill / Ball Mill Machinery,Cement Ball Mill,Ball Mill Liner,Ball Mill from Mine Mill Supplier or Manufacturer-Henan Baichy Machinery Equipment Co., Ltd.

WhatsApp)

WhatsApp)