WhatsApp)

WhatsApp)

contaminated scales in coal boilers - crusherasia. contaminated scales in coal boilers in india . The Hindu : Cities / Tiruchirapalli : BHEL explores coal research . This could be fulfilled with a large-scale .Demand for coal has been growing faster than .

The undetected contamination of condensate returns is another common problem that leads to boiler feedwater contamination. Contaminants can vary from metals such as copper and iron to oils and process chemicals. Heavy metal contamination is usually a function of the construction materials of the process equipment and the condensate system.

Coal Ash, Fly Ash, Bottom Ash, and Boiler Slag ... there's boiler slag, the melted form of coal ash that can be found both in the filters of exhaust stacks and the boiler at the bottom. Even ...

contaminated scales in coal boilers . contaminated scales in coal boilers - crusherasia. contaminated scales in coal boilers in india . The Hindu : Cities / Tiruchirapalli : BHEL explores coal research This could be fulfilled with a large-scale Demand for coal has been growing faster than [email protected] > Get A Quote >

Clinkers resemble volcanic ash and lava. They occur in the high-temperature furnace area of the boiler. Clinkers form as a result of interaction among coal quality, boiler design and boiler operation. Coal boilers draw their combustion air from the bottom, up through the combustion grate.

contaminated scales in coal boilers . contaminated scales in coal boilers Clean Coal Technologies in Japan - NEDO. Blast furnace. DIOS. Steam coal. Coal. Steam coal. Pulverized coal. Combustion furnace boiler. Formed coke manufacturing technology .. in the gas may contaminate the fuel cells and the reactor catalyst and degrade.

Coal-fired boilers are mainly operated at either subcritical or supercritical conditions. From a thermo-physics perspective, two phase mixtures of water and steam are replaced by a single supercritical fluid when the boiler pressure increases above the critical pressure of 22.12 MPa and the corresponding saturation temperature of 374 °C (Shen and Cheng, 2004).

These mineral scales, along with sludge and process contaminants such as oils, can also cause an insulating effect which leads to overheating. The principal cause of mineral scale formation in boilers is the fact that scale-forming salt solubility decreases with increasing temperature.

In general, boiler deposits can cut operating efficiency, produce boiler damage, cause unscheduled boiler outages, and increase cleaning expense. The first anti-scaling preventative measure is to supply good quality demineralised water as make–up feed water. The purer the feed water is, the weaker the driving mechanism to form scale.

Finding contamination sources can be tough sometimes. The offending piece of equipment may only operate sporadically. By the time the condensate contamination is seen back at the boiler, the leaking piece of equipment may already be offline and any contaminated condensate flushed from its nearest condensate receiver.

contaminated scales in coal boilers in india. contaminated scales in coal boilers -, contaminated scales in coal boilers in india The Hindu : Cities / Tiruchirapalli : BHEL explores coal research, This could be fulfilled with a large-scale, » More; NRDC: Mercury Contamination in Fish - Know, Some of the major sources of mercury pollution in ...

contaminated scales in coal boilers in india The Hindu Cities Tiruchirapalli BHEL explores coal research This could be fulfilled with a largescale Demand for coal has been growing faster than . Four Boiler Contaminants that Jeopardize Power Plant. Silica is a major culprit behind the buildup of hard and dense scale inside the boilers and ...

Coal gas is combustible and was used for municipal lighting, and heating, before the advent of large scale production of natural gas from oil wells. In current practice, large-scale coal gasification installations are primarily for electricity generation, or for production of chemical feedstocks.

Sep 15, 2016· China will shut small coal boilers to cut pollution but LNG oversupply will remain. ... to increase as the country retires 400,000 small-scale coal boilers in the industrial sector by 2018, some ...

Why Does Coal Burn For So Long ? contaminated scales in coal boilers in india . Coal Fired Boiler . Learn More. environmental or operating problems than with normal coal fired boilers Today, the SNOXTM process is used in large scale on a coal fired power .

• Internal scales in furnace tubes can be measured in hundreds of points, as compared to one for standard DWD analysis. • Tube samples are taken only when needed where needed. • When scale growth is monitored frequently, corrective actions can be .

Prior to that time, formation of hard scale and severe corrosion led to boiler tube failures and explosions. Soda ash/washing soda (Na 2 CO 3) was the first chemical used to treat boiler water ...

Corrosion fatigue is influenced by boiler design, water chemistry, boiler water oxygen content, and boiler operation. A combination of these effects leads to the breakdown of the protective magnetite on the ID surface of the boiler tube. Loss of this protective scale exposes the tube to corrosion.

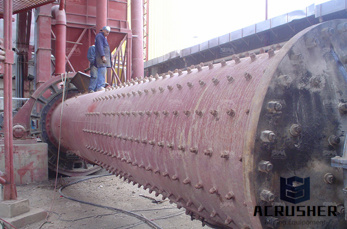

Chemical Cleaning Of Boilers - To Clean or Not To Clean Removing Deposits. Chemical cleaning has been considered a necessary part of boiler maintenance for many years. The objective of a chemical cleaning is to safely remove all the deposits from the inside of the boiler tubes.

Dec 15, 2010· Objectives of the Boiler Water Testing 1)To monitor the condition of the boiler water. 2)To control the chemical dosing of the boiler. 3)To maintain the boiler in healthy state, around any possible seawater contamination. The first stage in the boiler water testing is to collect feed water sample from the boiler concerned.

Coal. Four Boiler Contaminants that Jeopardize Power Plant Operation and Maintenance ... blowdown operations to bleed off a measure of contaminated water. ... build-up of hard and dense scale ...

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce electricity.Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator.The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine.

Jan 15, 2020· At >512-μm scale, there were three peak clusters observed in wavelet variations, corresponded to the three Fe-rich zones in the elemental maps of steel slag (Fig. 5f). For TMPs of coal ash, the peak association was only across three scales, indicating the size of the TMPs of coal ash particles were <64-μm.

The exact combinations in which they exist vary from boiler to boiler, and from location to location within a boiler (Table 12-1). Scale may form as calcium silicate in one boiler and as sodium iron silicate in another. ... Because of the extreme potential for deposit formation and steam contamination, no solids can be tolerated in ...

WhatsApp)

WhatsApp)