WhatsApp)

WhatsApp)

Industrial Grinding Machine MTW European Trapezium Mill Ball Mill Raymond Mill YGM Grinding Mill HGM Grinding Mill Industrial Drying Machine ... Lime shaft kiln, which also called vertical kiln, due to the vertical position of its kiln shell does not rotate, it is known as vertical kiln or shaft kiln. ... Mineral Slag Dryer Fly Ash Dryer ...

A horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill. Some operations apply the raw quicklime directly to the ore on the belt moving toward further crushing or grinding. In this application, it is necessary only to have a suitable lime storage tank with a live bin bottom and a means for metering the lime from the tank to the ore.

Lime is the high-temperature product of the calcination of limestone. Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing. To be classified as limestone, the rock must contain at least 50 percent calcium carbonate.

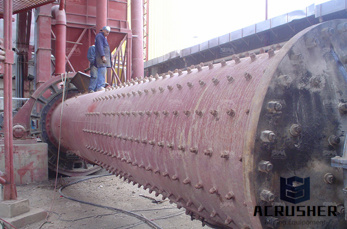

Ball mill is the key equipment for re-crushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals, and glass ceramic industry.

installe sole plate for ball mill "Create more value to customers" is the business philosophy of Xuanshi Machinery. We are always adhering to the "quality cast technology and strength, by the quality kimono to development" the road of development.

A Mill Relining Machine is a purpose designed machine used to remove and place liners in grinding mills. Typically, RME's Mill Relining Machines find application in the larger AG, SAG, Ball and Rod mills throughout the hard rock mining regions of the world.

Limestone Rod Mill,Mineral Rod Mill,Rotary Rod Mill,Ore Rod Mill. Limestone rod mill is one of the types of rod mill, which can be widely used in the . Industrial Grinding Machine The ball mill is formed with feeding part .

and mineral processing industry. ... circuits utilizing 2.3m diameter by 4.6m EGL packaged roller mounted ball mills. Each mill is capable of slaking pebble lime at a ... geared reducers are used exclusively on Lime Systems mills and all units have fully automated grease lubrication systems for the drive and idler shaft bearings.

Limestone can be directly processed into aggregated rock and burnt into unslaked lime which becomes slaked lime after its moisture & water absorption. The main content of slaked lime is Ca(OH)2. ... 4.Ball mill +classifying: High energy consumption, it is almost obsolete in nonmetallic mineral industry. ... then the powder is packed up by ...

As a result, the lime plant can work for a long period of time. Lime Processing Machinery. Lime calcining plant consists of a set of machines, while the lime kiln is the core equipment. Currently, there are mainly two kinds of lime kilns, one is rotary lime kiln and vertical lime kiln. Besides, there are many other machines.

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral processing, one example being the Sepro tyre drive Grinding Mill. Industrial ball mills can be as large as 8.5 m (28 ft) in diameter with a 22 MW motor, drawing approximately 0.0011% of the total world's power (see List of countries by ...

Alibaba offers 936 lime ball mill products. About 61% of these are mine mill. A wide variety of lime ball mill options are available to you, such as ac motor, dc motor, and stepper motor.

Lime Mineral Ball Mill Machine Palladinocafe. Ball mill powerful mineral grinding machine jxscall mills is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or .

Ball Mill For Grinding Lime Mortar.Ball Mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes. It works on the principle of impact: size reduction is done by impact as the balls drop from near the top of the shell.

Portland Cement Processing Plant Manufacturer. Capacity: 150 3000TPD . In cement plant, rotary kiln, ball mill is the indispensable equipment. rotary kiln . drier, and other equipments relate to metallurgy, cement, lime, mineral processing, . We would like to recommend a machine or production line suitable for you and. Live Chat

Figure 8.2 Media motion in the tumbling mill. 8.1 Grinding 8.1.1 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types - rod, ball, pebble autogenous and semi-autogenous. The grinding action is induced by relative motion between the

Preferential prices lime powder grinding ball mill machine with long durability Ball mill Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for ...

It is also faster to install than a traditional ball mill, significantly reducing initial costs. Lower operating cost. Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns.

This is actually what has happened wherever Mineral Jigs or Unit Flotation Cells have been installed in the ball mill classifier circuit. With the installation of one or both of these machines between the ball mill and classifier, as high as 70 per cent of the free gold and sulphide minerals can be immediately removed, thus reducing grinding ...

Ball mill grinding machine is a kind of horizontal drum-type grinding mill with external gear and double bins. Materials goes evenly through quill shaft in feeding device into the first bin, which has ladder lining or ripple lining with steel balls in different specifications.Steel balls are taken to a certain height by centrifugal force from ...

Jul 30, 2019· Lime processing plant is often equipped with either rotary lime kiln or vertical lime kiln. For lime kiln is the core equipment of the plant to produce burnt lime. Of course, except lime kiln, there are also other machines in the lime calcination plant. For example, there are crusher, dust collector, packing machine, transferring systems and so on.

Manufacturer and turnkey systems integrator of leather, mineral, ore, resin, pitch, lime and limestone grinding mills. Air classifier, hammer, pin, and powder grinding mills; and table top lab systems are available. Offered in size ranging from 1 hp to .

Lime ball mill advantages. 1. The lime ball mill adopts rolling bearings instead of sliding bearings, which greatly reduces friction, easy starting and significant energy saving; 2. It adopts a cone design at the discharge end. This not only increases the volume, but also forces the steel ball .

The centrepiece of RME's mill relining system is a RUSSELL 7 or RUSSELL 8 (seven or eight axis) liner placement mill relining machine. Available in maximum liner capacities from 500kg to 7,500kg, these machines represent the ultimate in new liner replacement capability.

WhatsApp)

WhatsApp)