WhatsApp)

WhatsApp)

Grinding Plants with Vertical Mills. ... cement raw grinding plant: 1999: development, ... Ball mill 240/400 inspection tube mills: coal grinding plant: 2011: ... Cement Industry - Plant Process Audits - Featured Industry. A Plant Process Audit is a comprehensive evaluation ... Plant audits evaluate the operation of a cement plant ...

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time

Nov 16, 2011· Process in vertical raw mill. This feature is not available right now. Please try again later.

Vertical Raw Mill In Cement Industry, vertical raw mill cement industry. vertical raw mill cement industry pdf download at Free PDF Search Engine For Tons of . Cement Vertical Roller Mill - gwmcn. Cement Vertical roller mill Industry reports; This cement mill is widely used in the grinding of cement raw .

Vertical Roller Mills for grinding in Coal, Raw and Cement: Range: B1PV 80 to B1PV 200, Power up to 2,000 kw: Applications. Vertical Roller Mill; Vertical Coal Pulverizer; Industries. Cement Industry; Power Industry; DOWNLOADS. ELECON_VERTICAL_ROLLER_MILLS_DRIVE_CATALOGUE.pdf [1.27 ] Proud Members of. Elecon Group Companies ...

Vertical Roller Mill In Cement Industry Atox Roller Lubrication. Crush concrete into gravel motor de trucos soul crush di facebook beans crushing maching crush concrete into gravel vertical roller mill services atox vertical roller mill pdf raw mill roller lubrication atox raw mill gear box system vertical grinding mill lubrication system system lubrication new atox mill

Feb 17, 2016· In this training module, we'll cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw .

May 15, 2013· Vertical raw mill pradeep kumar 1. Vertical raw millK.P.PRADEEP KUMARSr G M OperationKarikkali WorksChettinad Cements Ltd 2. The principle of vertical millresembles like ammi kallu, attaankallu,Or ennai chekku vandi 3. History of grinding technology 4.

Available and Emerging Technologies for Reducing Greenhouse Gas Emissions from the Portland Cement Industry Prepared by the Sector Policies and Programs Division Office of Air Quality Planning and Standards U.S. Environmental Protection Agency .

Cement Process & Energy Saving October, 2006 The Energy Conservation Center, Japan Tro Kawase. Laos 2006.10 2 ... mill by vertical roller mill 3)Pneumatic transfer of raw material to mechanical transfer Third step ... Elec Cons in Raw Mill kWh/d Cement Production ton/d Elec Cons in Cement .

Vertical Raw Mill Cement Industry vertical raw mill cement industry Description : Rawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill For this reason, the ...

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency.

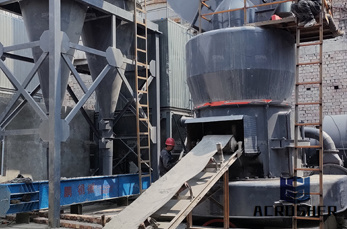

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and mining fields, and are also used to process gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials.

Thailand: Siam Cement has ordered a LM 56.3+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce medium-fine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM 56.3+3 CS mill from Loesche for its Ta Luang cement plant in 2014.

Sep 17, 2015· 04 Raw Mill Building VRM The raw material is finish-ground before being fed into the kiln for clinkering. This grinding is done using either ball mills or vertical roller mills (VRM). VRM uses the compression principle to grind the raw material.

Aug 30, 2012· Raw mix is stored in a pre-homogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Pre-heating Raw Material. After final grinding, the material is ready to face the pre-heating chamber. Pre-heater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln.

With scientific & reasonable design and its unique advantages, HLM vertical roller mills are applied widely in power, metallurgical, cement, chemical and non-metallic industry, for grinding of various materials, such as cement raw material, clinker, limestone, slag, .

is employed for coal grinding mills and mills in the cement and industrial minerals industry. 2, 3, 4 or even 6 grinding roller con-figurations for a single grinding table can be realised. The first Type LM 26.3 D modular coal grinding mills were devel-oped in 1980 and employed for 12 times 2x600 MW power sta-

MVR vertical roller mill with MultiDrive ... No matter what type of material has to be ground – cement raw material, cement clinker or granulated blast-furnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the clock, reliably and on the long term ...

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Cl

Request PDF on ResearchGate | Reducing energy consumption of a raw mill in cement industry | Several grinding methods are available in cement industry depending upon the material to be ground. In ...

Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blast-furnace slag with small to medium output rates, the MVR mill with conventional drive is .

WhatsApp)

WhatsApp)